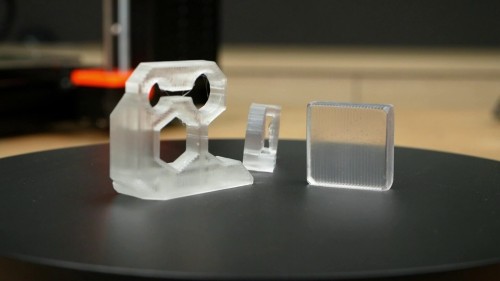

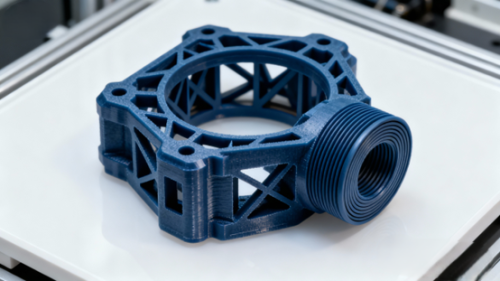

PLA is a biodegradable thermoplastic derived from renewable resources It prints at relatively low temperature, has minimal warping, and is user-friendly — making it very popular for hobbyist and educational use. However, it has relatively low heat-resistance and is more brittle compared with some engineering plastics. Typical uses: Decorative items, concept models,